Clarecastle

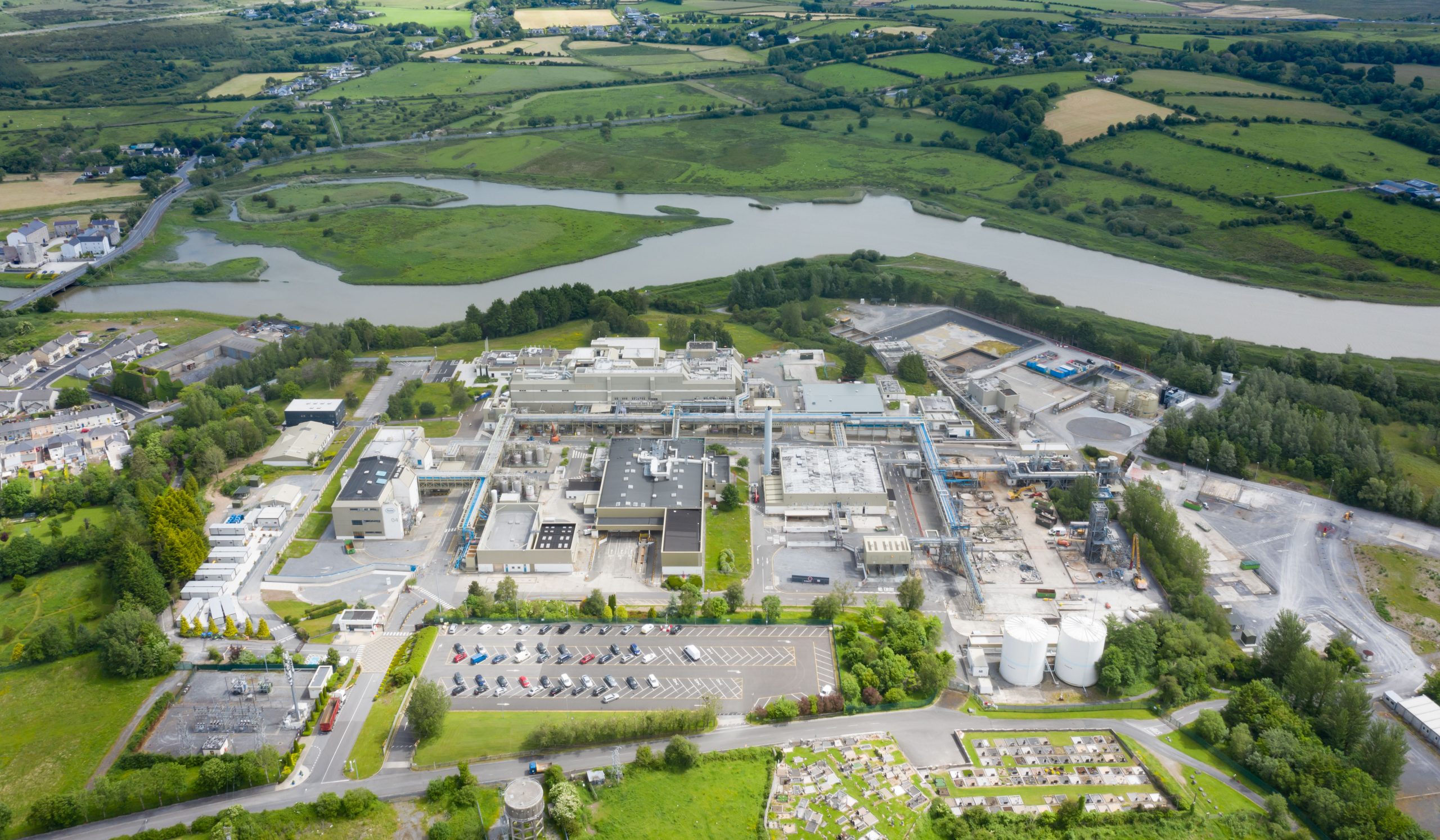

The Clarecastle project at Roche, Ireland, stands as a testament to our expertise in industrial demolition. The project involved asbestos removal, decontamination, de-planting, and demolition of a key pharmaceutical production site that had been operational for over four decades.

The 88-acre site housed 10 buildings constructed in the 1970s, encompassing over 300,000 square meters of offices and facilities, with more than 200 pieces of equipment and approximately 210 kilometres of pipework. Following the cessation of production in March 2020, Erith undertook the task of clearing the site, which included the demolition of two significant production facility buildings, support buildings, and tank farm areas.

300,000

sqm site

210

km pipework

30,000

tonnes of concrete processed

The complex nature of the construction presented significant engineering challenges. Erith managed these challenges safely and strategically, adhering to the project timeline. The site’s status as a major COMAH hazard required meticulous decontamination and de-planting under stringent ATEX controls. Whilst bulk decontaminated by the client, the clean to shell and de-plant had to be carried out under onerous controls as several elements of the process equipment could not be decontaminated until opened through the de-plant process.

We utilised Hitachi 890 and 670 class excavators for primary demolition, supported by a fleet of CAT 30- and 40-ton excavators. The team also processed 30,000 tonnes of concrete materials for future site remediation.

Technological advancements played a significant role in enhancing efficiency, with the deployment of Mavic Pro Drones for site surveying, laser scanning for capturing detailed site information, point cloud technology for virtual site walkthroughs, and the use of the last planner system for focused activity planning. Our commitment to community engagement was evident through the employment of local individuals and the provision of necessary training for careers in demolition.

The successful completion of the demolition and associated works has laid the groundwork for future development opportunities at the site, showcasing our capability to handle complex industrial projects with precision and care for the environment and the community.